Secondary Smelting and Alloying of Aluminum - Market Size, Financial Statistics, Industry Trends

Industry Overview

This U.S. industry comprises establishments primarily engaged in (1) recovering aluminum and aluminum alloys from scrap and/or dross (i.e., secondary smelting) and making billet or ingot (except by rolling) and/or (2) manufacturing alloys, powder, paste, or flake from purchased aluminum. Cross-References. Establishments primarily engaged in--Source: U.S. Census Bureau

Secondary Smelting and Alloying of Aluminum Market Size

This report includes historical and forecasted market sizes and industry trends for Secondary Smelting and Alloying of Aluminum. It reveals overall market dynamics from 2021 through the present, and predicts industry growth or shrinkage through 2031. Revenue data include both public and private companies in the Secondary Smelting and Alloying of Aluminum industry.| Historical | Forecasted | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2021 | 2022 | 2023 | 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | 2031 | |

| Market Size (Total Revenue) | Included in Report |

||||||||||

| % Growth Rate | |||||||||||

| Number of Companies | |||||||||||

| Total Employees | |||||||||||

| Average Revenue per Company | |||||||||||

| Average Employees per Company | |||||||||||

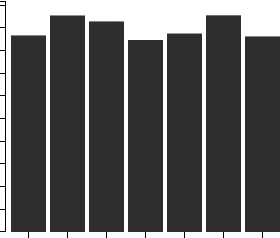

Industry Revenue ($ Billions)

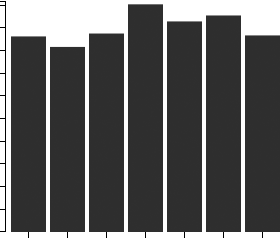

Industry Forecast ($ Billions)

Pell Research's advanced econometric models forecast five years of industry growth based on short- and long-term trend analysis. Market size statistics include revenue generated from all products and services sold within the Secondary Smelting and Alloying of Aluminum industry.

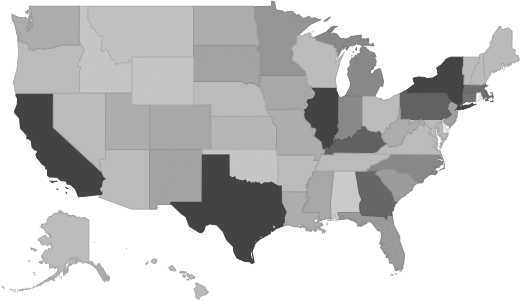

Geographic Breakdown by U.S. State

Secondary Smelting and Alloying of Aluminum market share by state pinpoints local opportunities based on regional revenue statistics. Growth rate for each state is affected by regional economic conditions. Data by state can be used to locate profitable and nonprofitable locations for Secondary Smelting and Alloying of Aluminum companies in the United States.Industry Revenue by State

Distribution by Company Size

| Company Size | All Industries | Secondary Smelting and Alloying of Aluminum |

|---|---|---|

| Small Business (< 5 Employees) | Included |

|

| Small Business (5 - 20) | ||

| Midsized Business (20 - 100) | ||

| Large Business (100 - 500) | ||

| Enterprise (> 500) | ||

Industry Income Statement (Average Financial Metrics)

Financial statement analysis determines averages for the following industry forces:- Cost of goods sold

- Compensation of officers

- Salaries and wages

- Employee benefit programs

- Rent paid

- Advertising and marketing budgets

The report includes a traditional income statement from an "average" Secondary Smelting and Alloying of Aluminum company (both public and private companies are included).

| Industry Average | Percent of Sales | |

|---|---|---|

| Total Revenue | Included |

|

| Operating Revenue | ||

| Cost of Goods Sold (COGS) | ||

| Gross Profit | ||

| Operating Expenses | ||

| Operating Income | ||

| Non-Operating Income | ||

| Earnings Before Interest and Taxes (EBIT) | ||

| Interest Expense | ||

| Earnings Before Taxes | ||

| Income Tax | ||

| Net Profit | ||

Average Income Statement

Cost of Goods Sold

Salaries, Wages, and Benefits

Rent

Advertising

Depreciation and Amortization

Officer Compensation

Net Income

Financial Ratio Analysis

Financial ratios allow a company's performance to be compared against that of its peers.| Financial Ratio | Industry Average |

|---|---|

| Profitability Ratios | Included |

| Profit Margin | |

| ROE | |

| ROA | |

| Liquidity Ratios | |

| Current Ratio | |

| Quick Ratio | |

| Activity Ratios | |

| Average Collection Period | |

| Asset Turnover Ratio | |

| Receivables Turnover Ratio | |

| Inventory Conversion Ratio |

Products and Services Mix

Product lines and services in the Secondary Smelting and Alloying of Aluminum industry accounting for the largest revenue sources.| Product Description | Description | Revenue ($ Millions) |

|

|---|---|---|---|

Secondary smelting and alloying of aluminum |

Included |

||

Aluminum ingot, including billet, made by secondary smelters |

|||

Aluminum/Al-base alloy powders/paste/flakes, purch. Al |

|||

Secondary smelting and alloying of aluminum, nsk, total |

|||

Secondary smelting/alloying of Al, nsk, nonadmin-records |

|||

Secondary smelting/alloying of Al, nsk, admin-records |

|||

Compensation and Salary Surveys

Salary information for employees working in the Secondary Smelting and Alloying of Aluminum industry.| Title | Percent of Workforce | Bottom Quartile | Average (Median) Salary | Upper Quartile |

|---|---|---|---|---|

| Management Occupations | 4% |

Included |

||

| Chief Executives | 0% | |||

| General and Operations Managers | 1% | |||

| Office and Administrative Support Occupations | 7% | |||

| Installation, Maintenance, and Repair Occupations | 12% | |||

| Other Installation, Maintenance, and Repair Occupations | 10% | |||

| Industrial Machinery Installation, Repair, and Maintenance Workers | 6% | |||

| Production Occupations | 56% | |||

| Metal Workers and Plastic Workers | 34% | |||

| Forming Machine Setters, Operators, and Tenders, Metal and Plastic | 7% | |||

| Extruding and Drawing Machine Setters, Operators, and Tenders, Metal and Plastic | 6% | |||

| Machine Tool Cutting Setters, Operators, and Tenders, Metal and Plastic | 9% | |||

| Cutting, Punching, and Press Machine Setters, Operators, and Tenders, Metal and Plastic | 7% | |||

| Metal Furnace Operators, Tenders, Pourers, and Casters | 7% | |||

| Metal-Refining Furnace Operators and Tenders | 5% | |||

| Other Production Occupations | 15% | |||

| Miscellaneous Production Workers | 8% | |||

| Transportation and Material Moving Occupations | 11% | |||

| Material Moving Workers | 9% | |||

| Laborers and Material Movers, Hand | 7% | |||

Government Contracts

The federal government spent an annual total of $2,984,755 on the Secondary Smelting and Alloying of Aluminum industry. It has awarded 8 contracts to 4 companies, with an average value of $746,189 per company.Top Companies in Secondary Smelting and Alloying of Aluminum and Adjacent Industries

| Company | Address | Revenue ($ Millions) |

|---|---|---|

Included |

||